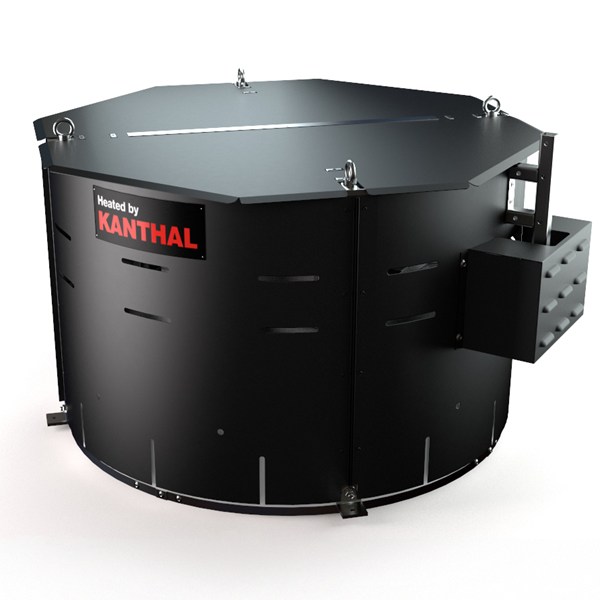

Sandvik is now introducing its next generation of Kanthal electrical ladle heaters. By heating ladles with electricity instead of gas, aluminum producers and steel foundries can benefit from lower energy costs, increased process control, reduced CO2 emissions, and a cleaner working environment.

High net efficiency

Kanthal electrical ladle heaters offer net efficiency of 70%, compared to only 20% for gas. Their design enables the same heater tube to be used for both heating and holding. The heating elements are arranged in a reflector, allowing the radiation to be more accurately directed towards the target area.

The uniform temperature profile achieved when using electrical elements to heat the ladle, and the fact that there is no flame or streaming hot exhausts, will prolong the lifetime of the refractory by 10–15%.

Innovative monitoring and control

An advanced heater monitoring and control system optimizes performance and prolongs the lifetime of the heater by eliminating overheating. The system ensures maximum and consistent power, which reduces process times.

Kanthal electrical ladle heaters are supplied as complete installations, comprising heating elements in a reflector casing, and control and regulation equipment. Commissioning and technical support are provided on site by Sandvik heating experts.

Complete range

Sandvik offers a broad portfolio of Kanthal electrical heating systems, for a range of applications in the primary aluminum industry, typically rodding shops, in secondary aluminum in foundries, and in steel foundries. We also provide systems for glass production and R&D purposes. |